The Schottky diodes are not new components. They are already in use for over 25 years, mainly in the power supply industry.

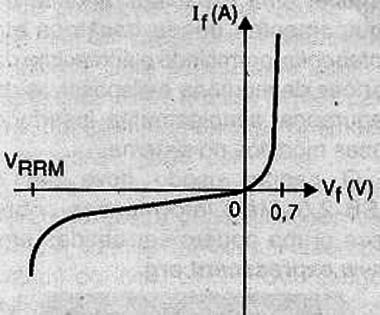

But what have these diodes different from others? When we analyze the characteristic curve of the common diodes, to see that they start to conduce only when a minumum voltage is reached. This voltage is necessary to break the potential barrier which manifests itself at the junction of the diode. For common types such as silicon diodes, this barrier requires a voltage of the order of 0.7 V, as shown in Figure 1.

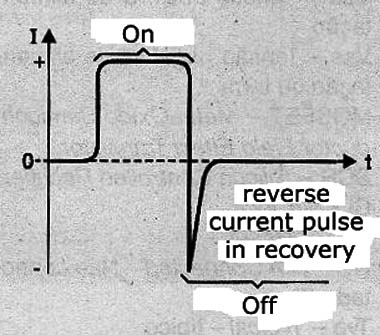

We also note that ordinary diodes such as silicon used in power sources are slow devices need some time to start driving and more time to recover from the conducting state when the polarity of the applied voltage is reversed.

This reverse recovery time or "reverse recovery" is especially important in many applications. What occurs is that in reverse the polarization of a diode, so it passes the conduction state to non-conduction in the diode process interval does not block the current and conducts yet even when the voltage has been inverted, as shown in figure 2.

Although the time at which this occurs is quite small, there sensitive applications, particularly those in which the diode must switch quickly, it is not accepted. These undesirable characteristics in common diodes are overcome in large part by Schottky diodes.

The Schottky Diode

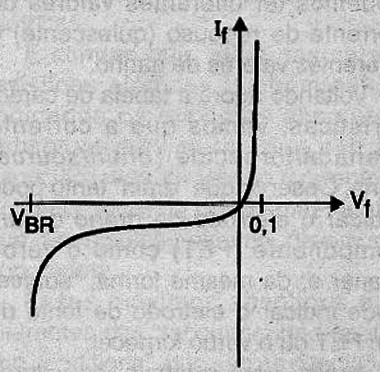

Firstly, the Schottky diodes start to conduct with an extremely low voltage, much lower than those of ordinary silicon diodes used in rectification. In addition, the leakage current flowing for a Schottky diode when biased in the reverse direction is lower than that found in silicon diodes, as shown in Figure 3.

The switching time, moreover, is extremely low, of the order of less than 100 picoseconds, which allows its use in very high frequency circuits. For the reverse recovery time also we have excellent characteristics in these diodes.

Besides the times are very short, recovery is smooth, which ensures "overshoot" very small reverse when they switch from full conduction state for not conducing.

In practice it has some important benefits, such as no need to use “snubber” filters circuit in order to avoid the appearance of high voltages due to switching of high speed devices.

In practice

The first problem that the designer who wants to use Schottky diodes find is that the common types rarely have reverse voltages that exceed 100 V (Vrrm).

The problem is that, when making Schottky diodes with higher reverse voltages, also increases the direct voltage required to drive and then its driving properties are close to the common diodes, so there is no advantage in using them.

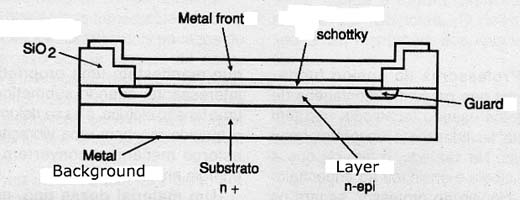

The properties of Schottky diodes are determined by the height of the energy barrier material deposited on silicon in the manufacturing process. A metal with a lower energy barrier minimizes direct voltage but also restricts the operation ability at high temperatures. Furthermore pass occurring currents larger leak.

On the other hand, a higher temperature and barrier minimizes leakage, but increases the forward voltage needed for conduction. Thus, depending on the application, the manufacturers must play with these characteristics in order to obtain a diode having the desired characteristics. Figure 4 is an example of the structure adopted for the production of a Schottky diode by Microsemi.

In this structure we have a ring that surrounds the p-n region which functions with suppressor for absorbing reverse energy. Anyway, we can find a wide variety of circuits requiring rectification mainly in high yield stresses and low losses at high frequencies, which make use of Schottky diodes.