Soda cooler

Cheaper than the cooler spray is this alternative solution we have shown. If you have a device that has intermittent problems and you suspect heating transistors or integrated circuits, a refreshment straw can help you find the source of the problem.

When the appliance problem manifests, blow the straw over the suspect component. The airflow will cool you down quickly, and if the defect goes away with it, the problem is with its discovered source. Of course, this makeshift solution is for those who do not have a cooler spray on their workbench, which is the ideal solution for discovering this kind of problem.

Using leaking diodes

Small diodes with leakage that cannot be used in more critical applications, but can be used in power supplies where currents are greater than about 20 mA. This can be done with diodes that have leakage resistances of not less than 50 k ohm. These diodes can still be used as rectifiers because the current they pass in reverse is minimal. Of course, one should be aware of the maximum current they can drive in the right direction.

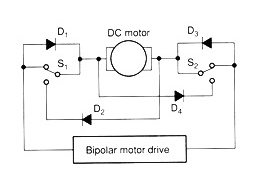

DC motor brake

One way to brake a DC motor is to short its coil terminals. The tension generated by the movement is short-circuited, generating a counter-motion force, tending to rapid braking. This can be done with a key and diodes as shown in figure 2.

This solution is especially suitable for mechatronics applications (automation and robotics) where a quick stop of a mechanism driven by a DC motor is required.

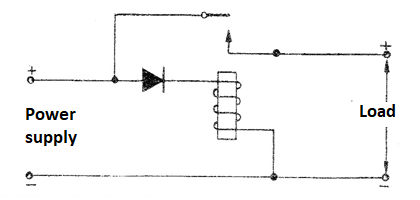

Reverse polarity protection

In Figure 3 we have a simple circuit that protects a load in case of an accidental inversion of the polarity inversion of the power supply.

The relay used must have the same voltage as the source used and the current diode according to its drive. For relays up to 100 mA 1N4148 can be used and for larger currents 1N4002 or 1N4004.

Although there are simple diode circuits, the advantage of this circuit is that there is no voltage drop, as occurs in circuits that use semiconductors.

Measuring the power of a motor

To measure the power sourced or drained by a small DC motor, use the circuit in figure 4. The ammerter is connected in series and the voltmeter is connected in parallel. Feed the motor to its working voltage and make it exert the force it needs in its normal application, eventually gripping its shaft to force it. Write down the voltage and current. The product of tension by current is power.

For example, 6 V x 300 mA = 6 x 0.3 = 1.8 W

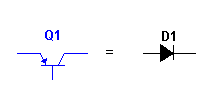

Improvising germanium diodes

In the absence of germanium diodes such as 1N60 or 1N34 for a radio receiver, field strength meter and other designs, we can replace this component with an old germanium transistor taken from disused transistor radio like the 2SB74, OC74, 2N107 and many others over 30 or 40 years old. What we do is take advantage of the base-emitter junction of these normally PNP-type transistors by connecting them as shown in Figure 5.

Similarly, silicon diodes with general purpose silicon transistors such as the BC558 can be improvised.

Problems with potentiometers

The wear of the graphite trails by the cursor movement and dust accumulation may be responsible for defects in common potentiometers. This defect manifests unpleasantly on the volume controls of radios and amplifiers, producing “scratches” and “clicks” as we increase or decrease the sound intensity. In some cases the potentiometer really needs to be replaced when the defect manifests but in others a Cleaning can greatly improve its functioning.

This cleaning can be simplified without opening the component by dripping a few drops of acetone or benzine into the component and rapidly increasing and decreasing the volume. The liquid will dissolve some of the dirt causing the problem by removing it from the graphite trail.

After a few seconds this operation has been done, and the liquid has evaporated you can turn on the unit, noting that always a good improvement in sound quality.

If the defect is not remedied with this procedure it is a sign that the potentiometer needs to be replaced.