Note: this article is from 2005 - The same project can be implemented with more modern versions of MSP430.

Gas Consumption Meter

One of the projects we analyzed, using the MSP430 in previous editions, was a very versatile electric power consumption meter, both for the possibility of directly driving a liquid crystal display, and also for transmitting through a wireless interface the measurement result to a remote read receiver.

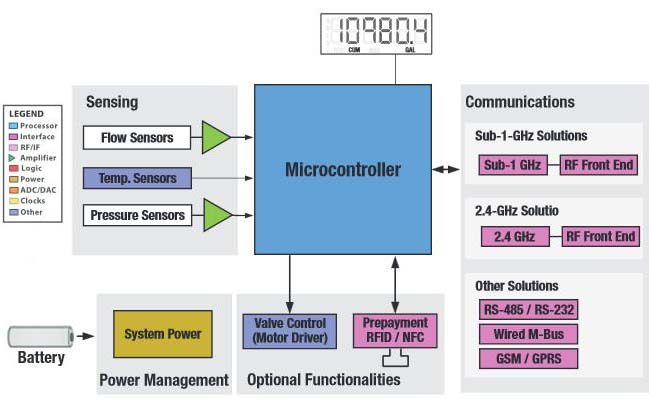

This same design, according to the Texas application manual SLAU028 (*) Getting Started with the MSP430 Microcontroller can be used to measure gas flow or consumption in either domestic or industrial applications.

In Figure 1 we have the complete diagram of the meter suggested by Texas Instruments in a first version which uses sensors that can be either mechanical or electronic.

(*) The complete manual with all the information on using the MSP430 can be obtained on the Internet at http://www.ti.com.

The circuit can use either mechanical or electronic interface. The mechanical interface uses contacts to send information to the processor about the volume of gas consumed.

The Oz output is used for sweeping, reducing the consumption of one of the contacts being locked at the “on” position.

For the electronic interface version the signals are selected and are read with a 90 degree lag in order to distinguish the flow direction.

The circuit also measures the temperature of the gas using the ADC converter.

This is important in this type of application because it allows greater accuracy in reading the volume, since this depends on the temperature..

Any combination of elements can be used depending on the application the circuit is intended to.

In this application the MSP430 operates in a low power mode with a current of 1.6uA (nominal) but all enabled interruption sources remain on.

These interruptions are:

Volume interface: any change in volume when the Oz output is active.

Basic timer which continuously powers the timer and can be switched on in a very large range of times (2 to the power of -16 seconds to 2 seconds).

This frequency is derived from the 32 kHz crystal.

Key Push - Port0 entries have interrupt capability.

Activity M-BS via interrupt P0.0 (RCD)

Inserting a card into the card interface.

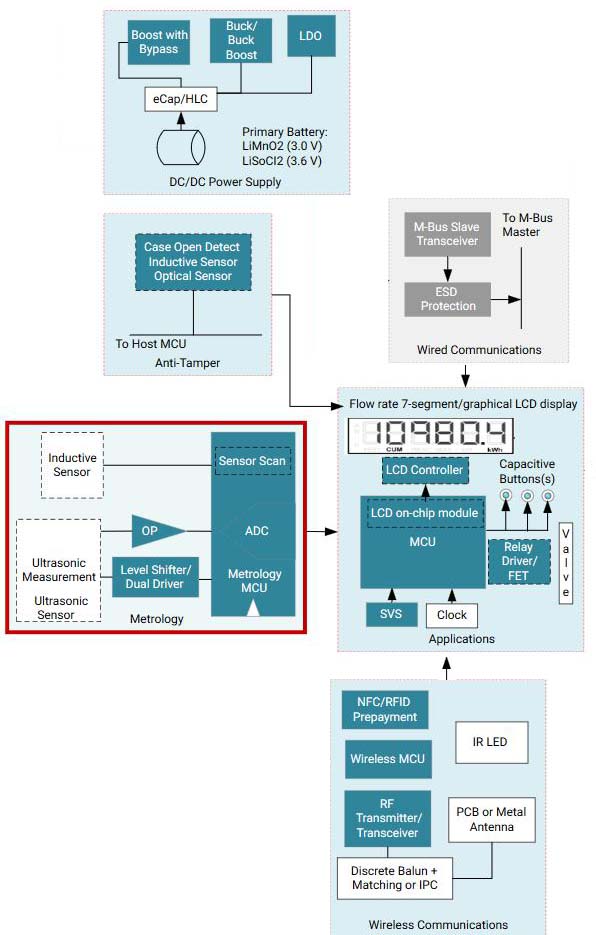

A second version for the circuit is shown in Figure 2 and contains EEPROMs which are usually already available on the MSP430C33x chip.

The 128k x 8-bit EEPROM is attached to the MSP430 to store the measured gas volume information.

With this feature the gas products can either predict the independent consumption of the consumer in which the appliance is installed but also determine it in the case of a prepaid sale, for example.

See more: www.ti.com/solution/gas_meter

Water Consumption Meter

Of course, anything that can be sold or supplied in quantities which can be measured by a sensor is amenable to the application of the MSP430 as a meter.

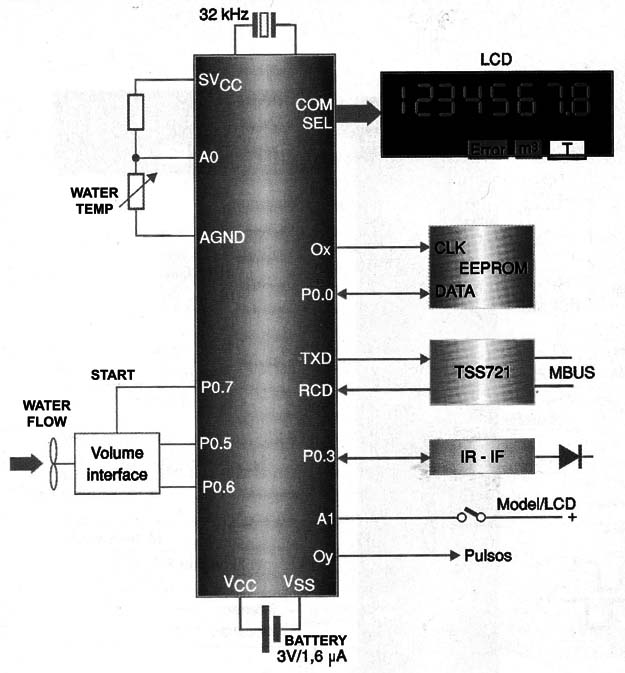

This is the case of water consumption where we can have a very simple practical circuit based on the MSP430, as shown in Figure 3.

This circuit can be used to measure the domestic consumption of water or to control the flow of water in a reservoir or an application which requires this type of measurement.

In this circuit, the volume interface measures the flow of water in a conduit in a conventional way, sending this information to the read ports P5 and P6.

An important feature of the signals sent is that they are 90 degree lag pulses which allows detecting the direction of rotation of the sensor and therefore the direction of the water flow.

The operating principle of this application is the same as for previous applications.

We suggest that the reader look in the recommended literature or in the previous articles for the MSP430 where we describe the meter of power consumption information about the operation of the microcontroller.

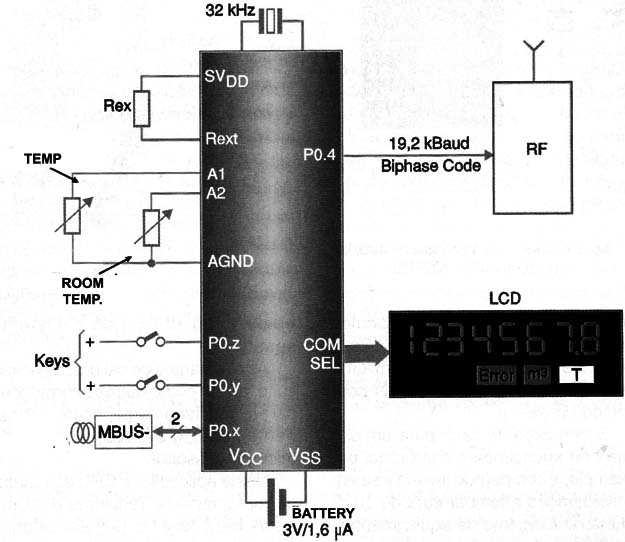

Heat Consumption Meter

This application can be used in industry to measure the heat consumption of a machine or what is sent to an equipment through a liquid or gas stream or even in commercial and domestic air conditioning systems of several types.

The principle of operation of the MSP430 in this application is the same as before: a sensor measures the presence of the heat transfer element and sends this information to the MSP430 in digital form (pulses).

In this case we have four controls to consider: the own control of the heating elements in case they are electric, as in the example, elements of a domestic air conditioning system, the switches and finally the sensor.

Note that in this circuit, in addition to the indication on a liquid crystal display, we can also connect a remote reading interface operating by radio signals.

The MSP430 has a serial modulation output which can be directly connected to transmitter modules of several types. This modulation output operates at a rate of 19.2 kilobauds with a biphase code.

The consumption of heat for a domestic heating system, for example, is calculated by taking into account the room temperature and the temperature of the heating element.

The results are calculated and recorded in the RAM for both on-screen display and later reading, using a wireless system.

The calibration constants of the circuit as well as other information for the operation are permanently stored in the microprocessor RAM.

In this application the CPU is "awakened" at regular intervals of 3 minutes to do the processing.

This allows the component to remain in a low-power condition most of the time.

Conclusion:

There are no limits to the instrumentation and control applications of the Texas Instruments MSP430 microprocessor.

In addition to the projects we have described in our series of articles and those presented in this article specifically, there are many others that are thoroughly analyzed in the component manuals, in particular the SLAU028 which can be accessed through the Internet on Texas’ site (http: //www.ti.com).

Some interesting ideas of projects that can be found in the document are: blood pressure meter, multimeter, battery charge meter and many others.

We remind you that programming this microprocessor requires an appropriate interface and software.

Texas Instruments provides the Starter Kit which contains both the programming manual with the appropriate software as well as the interface that enables individual programming of each microprocessor from the MSP430 series.