The body, for the most part, represents more than 95 percent of the size and weight of the component. it is clear that, if the body is reduced, we can gain space and profit, but on the other hand, we lose the ability to handle it. The basic idea of the SMD is to reduce the body to the minimum, in a way that only machines can handle it.

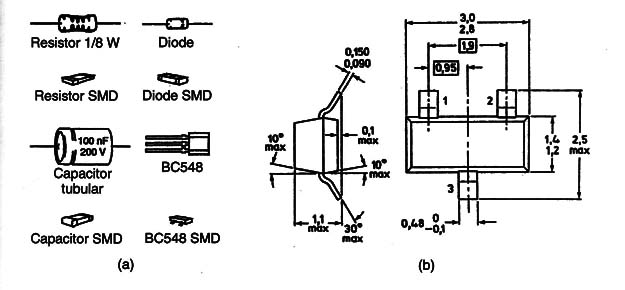

Reducing the size of the components in the equipment makes them cheaper, smaller, and lighter. Resistors, capacitors, diodes, transistors, and le can all be found in SMD versions as shown in Figure 1.

This figure shows the typical dimensions of these components and how they are mounted on a printed circuit board.

Special machines place the components on a board using glue and solder.

The working technology applied in this case is also called SMT (surface-mounting technology), so it is common to refer to devices used in this form as SMD and the technology as SMT.

It is important for the electrician to understand that the functions and the circuits are the same as those used in the common components.

The difference is only in the size and shape of the components. The main problem is how to handle them if a repair is needed.

Special kits, consisting of small tweezers, screwdrivers, and other delicate tools are available to help technicians replace SMD devices when repairing equipment.

The same dealers usually can furnish resistors, capacitors, and many other components in the SMD format as well.